Concrete Vibrators

Concrete Vibrators

Viber Internal Concrete Vibrators

Internal concrete vibrators use an external electric, pneumatic, or gasoline power unit to drive a vibrating head that produces rotary vibration to consolidate concrete. Properly consolidated concrete has fewer cracks and voids, is significantly more durable and less permeable, and has a smoother higher quality finish with fewer visible flaws (bugholes).

The Head is attached to the motor by a flexible drive that can be up to 35 feet long (or longer if care is used to prevent tight bends in the flexible drive). An eccentric (unbalanced) weight, inside the head, spins at a high rate to produce the vibration. The vibrating head is extended down into poured concrete to remove air bubbles, disperse the large aggregates, and ensure the cement fines are evenly distributed to coat the aggregates. Proper use of vibration means less water is needed, which produces stronger concrete. Air bubble removal and uniform cement-aggregate distribution produces concrete with a smoother finish. Please see "How to Consolidate Concrete" for further details.

External Concrete Vibrators

- External Vibrators remain “outside the pour” and deliver the vibration to consolidate concrete through the formwork. They are often used whenever a higher-quality exterior finish is desired. The most common External Concrete Vibrators used are pneumatic. Occasionally hydraulic and electric motors are used, although their lower frequencies will reduce the effectiveness of the vibration.

- External vibrators are mounted to the formwork using fixed or removable brackets, or they are permanently mounted using a channel-iron mount configuration. Due to variables in formwork and concrete consistencies, using External Vibrators may require additional preparation and planning to ensure satisfactory results.

- As with Internal Vibrators, External Vibrators use a rotating eccentric weight to produce vibrational force. The area-of-influence of the external vibrator is determined by the frequency and amplitude of the rotating mass, and by the way the vibrator is mounted. Please see "How to Consolidate Concrete" for more details.

There are many sizes and profiles of External Concrete Vibrators to suit your application:

- High frequency / High force Models

- High frequency / Medium force Models

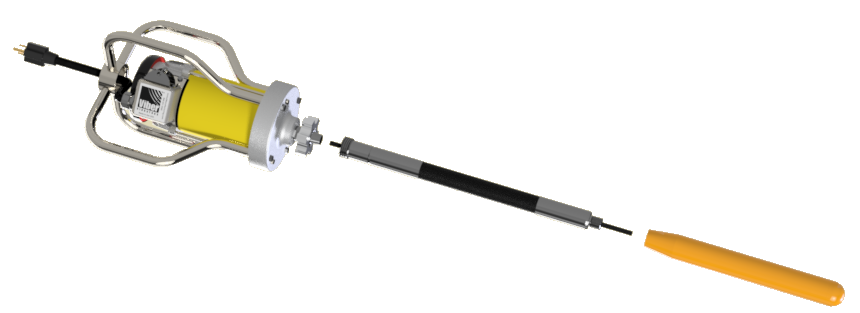

Viber® Internal Concrete Vibrator Systems consists of one each of the following three components:

-

Power Unit - Vibrators can be powered by any of the following:

-

Universal Electric Motors - all available in either 120V or 240V:

- VMK-1500

- VMK-2500

- VMK-2750

- VMK-3500

-

Patented Pneumatic Turbine Motors:

- VMP Turbo motor with cage or handle.

-

4-Cycle Gasoline Engines:

- VMG-2500 BP

- VMG-1750 BP

- VMG-1750 HH

-

Universal Electric Motors - all available in either 120V or 240V:

- Flexible Drive - Available in 7 lengths and 2 diameters. Flexible Drives can be coupled to provide longer lengths.

- Vibrating Head - Available in 6 diameters with either steel or rubber tips. Other specialty heads also available.

Note: All VIBER® components use identical fittings so that VIBER® components are completely interchangeable. Any flexible drive can be used with any of the power units and any of the heads. The interchangeability provides exceptional flexibility and greatly reduces the amount of the contractor's inventory. Operators select the best combination of head, flex-drive, and power source for their specific requirements. Please see the "Smart!Parts Selection Guide".

General selection guidelines for Concrete Vibrators:

- Operators select the best combination of head, flex-drive, and power source for their specific requirements. See the "Smart!Parts Selection Guide".

- Select drive length based on depth of concrete.

- Select power unit based on size of head and power source available. Please see "How to Consolidate Concrete" for more details.

System

System

Power Unit + Flexible Drive + Head = Smart!Parts™ System

You build the right Smart!Parts™ System for your application by choosing from the wide range of Viber® components including many different power options, different flexible drive lengths, and steel and rubber tipped vibrator heads or heads coated completely with polyurethane/polyurea. These components all use identical fittings so that Viber® components are completely interchangeable. Any flexible drive can be used with any of the power units (electric, pneumatic, or gasoline) and any of the heads. See Smart!Parts Selection Guide for recommendations to select the best Viber® power unit, head and flex drive for your application.

Choose the power unit:

Electric

Gasoline

Pneumatic

What flex drive length do you need?

What diameter Vibrator Head do you need for your application? Steel or Rubber Tipped or polyurethane coated?