Turboviber® Pneumatic Turbine Vibrators

TV-X and TCL Models

About Turboviber® TV-X and TCL Turbine Vibrators

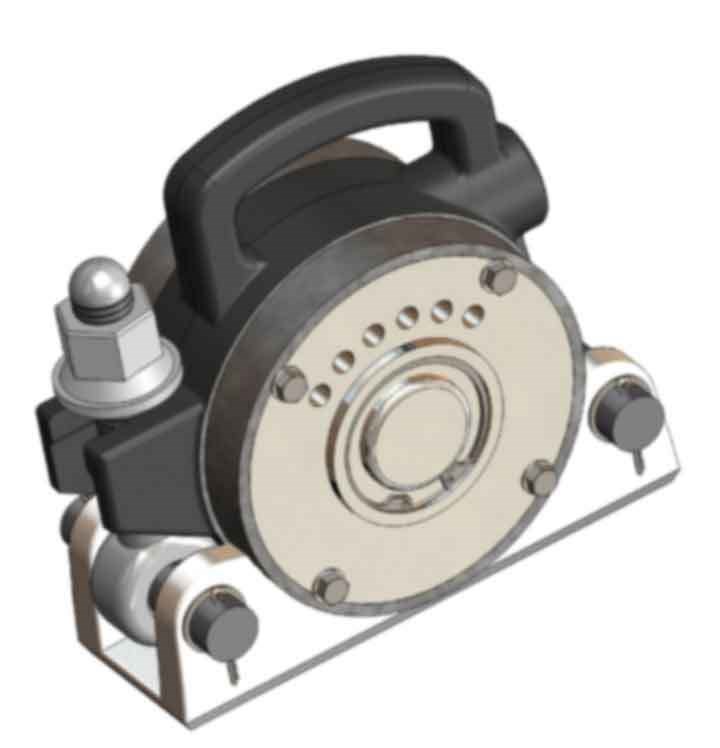

TCL Turbine

TV-X Turbine

Turboviber® Vibrators are highly efficient, patented vibrators, which produce much more force than the smaller Silver Sonic Turbine® Vibrators and Findeva's Golden Turbine Vibrators. They are the first pneumatic vibrator to ever handle dirty air and a dirty environment. The patented design helps pass dirt out of the vibrator. There are two model profiles; TV-X and TCL. The TV-X is a two-bolt heavy duty aluminum housing, which fits into a bracket. The TCL is a cradle lug ductile iron housing, which fits in the universal cradle lug wedge bracket used all over the world. Turboviber® vibrators operate at relatively high rpm producing high frequency vibration and large amounts of force. The largest Turboviber® Turbine Vibrator is capable of handling a load up to 54,870 pounds (24,889 kg). Use multiple vibrators on a single hopper when the load is greater than 54,870 pounds (24,889 kg). For example, to restore flow to a hopper with 100,000 pounds (45,359 kg), use two Turboviber® Vibrators. These vibrators are also used in concrete consolidation. For more information please see:

- Performance Data

- How to Select and Size an Industrial Vibrator

- How to Solve Flow Problems

- How to Consolidate Concrete

Advantages of Turboviber® Turbine Vibrators

- There are two Turboviber model profiles - TV-X and TCL.

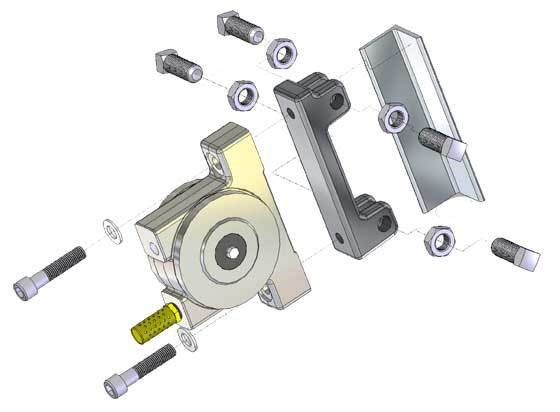

- The TV-X Turbine is a two-bolt heavy duty aluminum housing, which fits into a bracket.

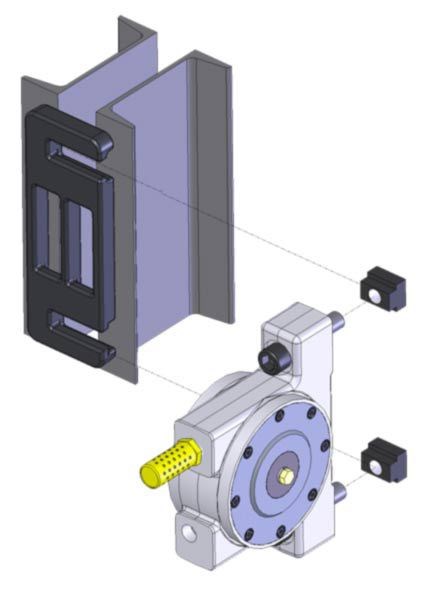

- The TCL Turbine is a cradle lug ductile iron housing, which fits in the universal cradle lug wedge bracket used all over the world.

- Durable in Harsh Environments - First pneumatic vibrator to ever handle dirty air and a dirty environment. Patented Design helps pass dirt out of vibrator.

- Highly Efficient - Revolutionary, patented turbine design will run on just 5 psi (.34 bar) using 1-3 CFM (28 - 85 LPM). More efficient than other pneumatic vibrators including other turbine vibrators.

- Simple, Dependable - Single moving part is the eccentric turbine wheel assembly that rides on high speed bearings.

- Large High Speed Bearings with special high speed grease assure long service life.

- Low Maintenance - Excellent choice for harsh environments such as precast concrete plants. The Turboviber vibrators are hassle free. A plant foreman said he has never used a vibrator so fantastic – it out lasted any other vibrators he has ever tried. He said the other vibrators he used would fill with dirt and seize up. He reduced his downtime because it never stopped working.

- No lubrication required.

- Easy Maintenance and Repair - No vanes or cylinders. The only parts that require replacement are the long-life bearings and oil seals.

- Turbine Repair Kits available; the TRK-50 and TRK-52 - see Accessories below.

- Excellent Concrete Consolidators - High rpm’s and high force produce smoothly finished concrete.

- Problem Solvers - The high force output and high frequency make them the best choice to solve flow problems for hard to move products like wet concrete, limestone, wet sand, fly ash, and coal fines. The frequency excites the fine particles and the high force moves the mass. Mount the vibrator to a bracket, insert in railcar hopper pocket, and unload stubborn materials from the railcar – it is just like turning on a faucet.

- Versatile - Easy to control force and frequency by adjusting air supply.

- Starts Every Time - Starts in any position. Orientation is not critical because it has no vanes.

- Permanent or Cradle-Lug Mount - The TV models fit a bracket for portability or can be bolted to a structure. TCL models fit in universal cradle lug brackets.

- Patented - All models are patent protected.

- Produces Uniform, Directional Flow.

Specifications

- Filtered air.

- 5 - 80 psi (.4 - 5.5 bar).

- 1 - 50 cfm (28 - 1,416 Lpm).

- No lubrication required.

- 85 - 95 dBA with muffler.

- Force output range up to 5487 force pounds (24,408 N) at 80 psi based on model used.

- Frequency range up to Up to 14,000 rpm @ 80 psi (5.5 bar) based on model used.

- Operate up to 80 psi (5.5 bar) – higher psi permissible but bearing wears out quickly and increases noise level.

- Maximum Ambient Temperature up to 220ºF (104ºC).

- TCL Turbine Operations Manual

- TVX Turbine Operations Manual

- TCL & TVX Dimensional Drawing

- TCL & TVX Dimensions

Accessories

- Manual Valves - 2-way manual ball valve used to turn the vibrator on and off for normal operation.

- Solenoids - For remote or automated control, use 2-way normally closed solenoid valve to turn the vibrator on and off for normal operation.

- Airline Kits - Required for trouble-free operation and long life of turbine vibrators. Includes airline filter, and pressure regulator with gauge.

- Sirometer - Convenient, compact rpm meter for measuring vibrator speed.

- Mufflers

- Hose Assembly - Makes air connection convenient. Please see the following hose kit information:

- Turbine Repair Kits:

- TRK-50 includes bearings, shaft, iron cap inserts , and 2 screws used to guide the cap into alignment upon assembly. The shaft presses into these inserts, which are pressed into the side plate, giving the vibrator longer wear.The inserts are designed to prevent fretting between the shaft and housing.

- TRK-52 includes 2 bearings and guide bolts.

- Mounting Brackets for TV-X vibrator movability:

-

Set Screw Mount Base Bracket (TVX/CC) - The bracket mounts to angle iron members, which are welded to a form or hopper. Four “pinch” set screws hold the vibrator firmly in place for high force output applications.

TVX CC

-

Mount Plate Bracket (TVX/MP) - Weld MP to a channel-iron on precast concrete forms, tunnel forms, or any steel surface. “T” slot bolts slide into the bracket and hold the vibrator firmly in place. Easily move vibrator - just loosen the nuts on the bolts and slide the vibrator out of the bracket.

TVX-MP Bracket

-

Wood Vice Clamp Bracket (TVX-VCW) - Simply clamp the VCW bracket to a 4” x 4” wood member by tightening a jack screw. Use only with TV-3X and TV-5X.

TVX VCW Bracket

-

- Mounting Brackets for TCL vibrator movability:

-

Cradle Lug Base (GCL Bracket) - Weld GCL bracket to a form or hopper. All vibrators with a cradle base housing fit this universal bracket. Slip vibrator lip snuggly into the cradle and tighten one nut.

TCL in Bracket

-

Cradle Lug with Wedge Base (GCL/GBM) - Wedge base fits in all railcar hopper pockets. Attach vibrator to bracket and slide into pocket for fast railcar unloading.

TCL GCL GBM Bracket

-

Selection of Turboviber Vibrators for Hoppers

For more details on selecting vibrators see:

- How to Select and Size an Industrial Vibrator

- How to Solve Flow Problems

- Turbine Vibrator Selection Guide

Selection of Turboviber Vibrators for Concrete Consolidation

A Turboviber turbine vibrator mounted on a form will “liquefy” the fresh concrete producing a denser, stronger, and a higher quality concrete product. Vibration causes the cement fines and aggregates to evenly distribute and the air bubbles to rise. The high rpm and high force output work together to produce a beautiful concrete finish.

- Selection of the TV-X or TCL turbine vibrator is based on the consistency of the concrete.

- Choose a vibrator that produces the amount of force specified in the table below.

- Vibrator spacing on forms is important and is also based on the concrete consistency. See table below.

- Note: When vibrating concrete, you need between 11,000 - 12,000 rpm's to 'excite' the cement, which causes it to adequately disperse throughout the mix.

- For more details on selecting vibrators for concrete consolidation see How to Consolidate Concrete.